Given the chance, I’ll run collets rather than multi-jaw chucks any day! Why? Collets offer superior concentricity (compared to a 3-jaw chuck), better grip, and can hold delicate items without crushing them. Furthermore, collet chucks are safer to use because they keep your lathe tools away from harm (via protruding nose) and don’t have sharp revolving jaws to cause damage. Here’s the story of setting up and testing my new Pratt Burnerd Atlas PB23 Quickie 5C collet chuck!

Lathe Workholding Essentials

If you want maximum versatility from your metal lathe, there are some workholding devices you must have in your collection! Each has their purpose, and some will be used rarely, but every job requires different tooling, so it’s great to have what you need in the shop.

Here are my “engine lathe workholding essentials”:

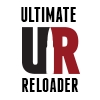

In the above picture we have:

- 3-Jaw chuck: high capacity and fast, but doesn’t have the best concentricity (work could show 0.002″ – 0.006″ of runout depending on the chuck and setup).

- 4-Jaw independent chuck: Awesome capacity, can dial in concentricity to 0.0001″ or less, slow to use.

- 5C collet chuck: 5C Collets themselves have about 0.0006″ runout, so net runout can be less than 0.001″ for the work being held.

- Faceplate: Ideal for holding irregularly shaped work with clamps, also used with lathe dogs to turn between centers

With these workholding devices, almost any metal turning scenario can be conquered. But there’s one collet system that’s most popular with lathe owners, and it’s no wonder why!

5C Collet System: King of the Metal Shop

There are MANY different types of collets designed for use with metal lathes- 3C, 2J, ER-series, Jacobs Rubberflex, 16C and many more. But 5C collets are the most popular.

Here are some reasons 5C collets are great:

- Easy to find, lots of options. You can find US-made, and imported 5C collets in a variety of different price brackets, quality levels, configurations (round, hex, square, and more). There’s a 5C collet for most any job, and most any budget.

- Capacity: 5C collets typically cover 1/32nd” all the way up to about 1 1/16″. This makes them very versatile for bar work.

- Versatile applications. You’ll find lathe chucks/adapters, milling fixtures, and other devices that use 5C collets- so your collet investment can provide value at the lathe, at the mill, and other scenarios as well!

- Emergency Collets: You can find “emergency collets” in a variety of materials including steel, brass, aluminum, and plastic. These “emergency collets” can be machined to hold work of any diameter within the 5C capacity range, and you can also create custom profiles (multiple steps, etc).

- Step collets: Step collets act like soft jaws in a 3 or 4 jaw chuck- you can hold work with diameters much greater than the typical capacity of the 5C collet system. You’ll also find machinable expanding arbors with 5C shanks.

Like anything else, these collets aren’t the best for everything but are perhaps the best all-around collet system for your average metal turning scenarios.

5C Collet Chuck Systems

Above: a 5C collet closer on an 11″ Logan lathe

Ther are many different types of 5C collet arrangements for various lathes including:

- Spindle nose adapters with lever closers: Fast, but specific to each lathe/spindle, requires more time to setup, can’t typically be used with an outboard spider.

- Scroll-type front-acting 5C collet chucks: Can be mounted and dismounted quickly, enable use of outboard spider, slow to tighten/loosen work.

- Handwheel-type collet chucks: Can be mounted and dismounted quickly, enable use of outboard spider, fast to use.

- 5C chucks clamped in place by multi-jaw chucks: Inexpensive, but require dialing in with a 4-jaw chuck to ensure maximum concentricity.

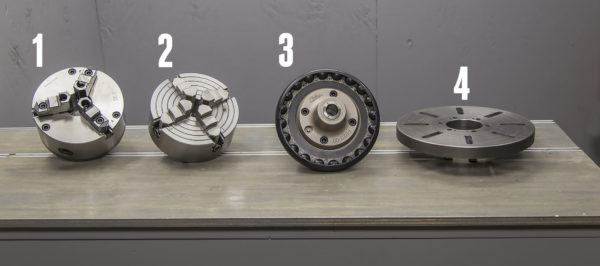

I personally like the handwheel type chuck best, and that’s why I just obtained a Pratt Burnerd Atlas PB23 Quickie 5C collet chuck for my lathe.

Atlas Quickie Handwheel PB23 Collet Chuck

Here are some reasons why I chose this chuck system:

- Quality- this chuck is beautifully machined and finished

- Quick operation: I really like the ability to step on the lathe brake foot bar, and tighten/loosen collets and work almost instantly

- Available mounts: My lathe has a less common D1-5 spindle, and this chuck was available with D1-5 mount ready to go, the chuck and backing plate available as a pair

- Easy mounting: It took just about 1/2 hour to unbox, clean, and mount this chuck

- Easy dial-in: I was able to “dial in” the chuck to about 0.0002″ TIR in about 15 minutes

From the Atlas product page:

Front Hand Wheel Quickie 5C Collet Chucks

- Fast and easy, front hand wheel operation

- Reduces operator fatigue

- Quick Change over Chuck to Collet Chuck – No linkages or drawtubes

- For 5C collets

- One year warranty

- Accurate-Maximum cone TIR .0005″

- Available in D type (camlock), A type, L type (long tapered nose) threaded, Flat Back and 4º taper

- Hand wheel teeth nitrided for longer life

- Body nickel plated for corrosion resistance

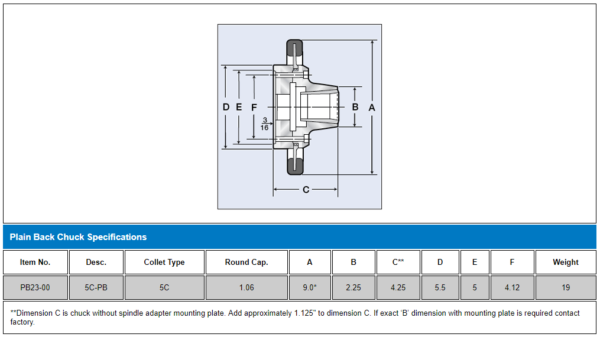

Here are the specifications for available configurations:

| D Type Cam-Lock Chuck Specifications | |||

|---|---|---|---|

| Item No. | Spindle | Round Cap. | Weight Lbs |

| PB23-D3 | D1-3 | 1.06 | 22 |

| PB23-D4 | D1-4 | 1.06 | 22 |

| PB23-D5 | D1-5 | 1.06 | 22 |

| PB23-D6 | D1-6 | 1.06 | 25 |

| PB23-D8 | D1-8 | 1.06 | 30 |

| PB23-D11 | D1-11 | 1.06 | 35 |

| A Type American Standard Chuck Specifications | |||

|---|---|---|---|

| Item No. | Spindle | Round Cap. | Weight Lbs |

| PB23-A4 | A1-4 | 1.06 | 22 |

| PB23-A5 | A1-5 | 1.06 | 22 |

| PB23-A6 | A1-6 | 1.06 | 25 |

| PB23-A8 | A1-8 | 1.06 | 28 |

| PB23-A11 | A1-11 | 1.06 | 33 |

| L Type American Standard Chuck Specifications | |||

|---|---|---|---|

| Item No. | Spindle | Round Cap. | Weight Lbs |

| PB23-L00 | L00 | 1.06 | 23 |

| PB23-L0 | L0 | 1.06 | 25 |

| PB23-L1 | L1 | 1.06 | 35 |

| PB23-L2 | L2 | 1.06 | 40 |

| Threaded Mount Chuck Specifications |

|||

|---|---|---|---|

| Item No. | Spindle | Round Cap. | Weight Lbs |

| PB23-41 | 1-1/2-8 | 1.06 | 23 |

| PB23-42 | 1-3/4-8 | 1.06 | 23 |

| PB23-43 | 2-1/4-8 | 1.06 | 23 |

| PB23-44 | 4° Taper | 1.06 | 25 |

| PB23-45 | 2-3/16-10 | 1.06 | 23 |

| PB23-46 | 2-3/8-6 | 1.06 | 23 |

Installation and Configuration

As was shown in the video above, installation is fast, and this chuck can be dialed in to very close tolerances for runout.

Here’s what I did to get this chuck out of the box, and ready for action:

- Remove packing materials, clean off preservative oil and packing particles

- Remove chuck from backing plate

- Clean mating surfaces on front of backing plate and back of chuck

- Mount backing plate on lathe (careful to torque mounting pins consistently)

- [optional] For D-type mounts, mark location of #1 pin on spindle and on chuck, or create witness mark across both

- Measure backing plate face runout, take approx. 0.005″ facing cut off backing plate face to true up

- Mount chuck to backing plate with four screws (barely tighten)

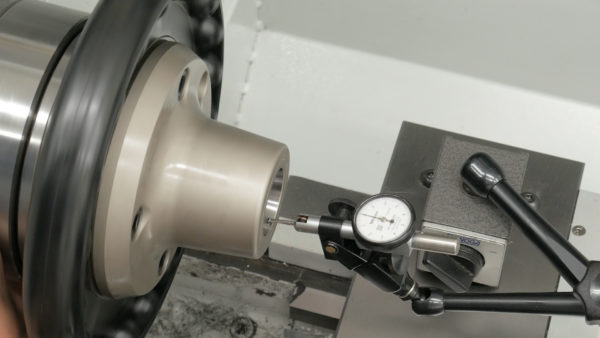

- Indicate ground taper inside collet nose opening (I started with .001″ indicator)

- Measure runout with indicator and lightly tap rim of chuck to align chuck

- [optional] Repeat steps 8-9 with 0.0001″ indicator until TIR falls within range you are comfortable with

That’s it! It only takes about 15 minutes to complete these steps if you have all of your tools ready to go. It’s really great to be able to quickly and accurately secure work in this chuck- even with delicate screw threads as the clamping surface!

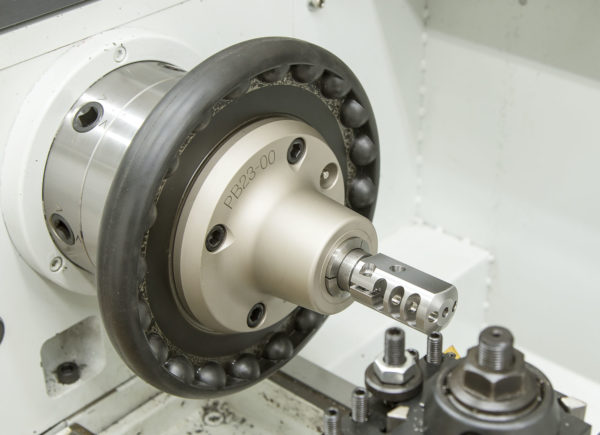

Here’s a mandrel I use for profiling muzzle brakes- a 5C collet is an ideal workholding solution for these types of tasks!

You’ll be seeing a lot more of this chuck on this website, and on the GavinToobe channel- so please stay tuned, and make sure you’re subscribed!

Do you have a favorite collet chuck or system? Please leave a comment!

Thanks,

Gavin

Gavin,

Truly feel good about your work.

Thank you,

John Szot