There are two pieces of machine shop equipment that are considered “essentials” for manual machine work: the metal lathe, and the milling machine. With these two machines, you can perform almost any common machining task. Here on Making with Metal, I’ve already posted a deep-dive on my Precision Matthews PM-1440GT metal lathe, and now it’s time to cover my Precision Matthews PM-949TV vertical milling machine.

I use this milling machine frequently, and here are my primary uses for this machine:

- Gunsmithing (inletting stocks, fine-tuning parts fit, cutting dovetails for sights, drilling gas ports for barrels, etc)

- Prototyping: making one-off parts, jigs, fixtures

- Tool-making

- General machining and fabrication (precision drilling, boring, slitting, milling, facing)

Let’s start with a tour of the machine!

Features and Specs

The Precision Matthews PM-949TV (variable speed head) and PM-949TS (step pulley head) milling machines are Bridgeport semi-clone machines. These machines are 100% made in Taiwan, are of premium construction, and are loaded with features.

From the Precision Matthews product page:

Model PM-949TS and PM-949TV High Precision Vertical Knee Type Milling Machines

Typical Users:

-

- Industrial users looking for a top quality, full featured vertical knee type milling machine, built for

industrial use - High end gunsmiths looking for the quality and features of a full sized, high quality knee mill

- Users who appreciate a high end, full featured knee type milling machine with the space saving

characteristics this offers, built for every day, professional use - Any other users who can appreciate a top quality machine with full features and no shortcuts, at a very reasonable price for the level of quality that you are purchasing

- Industrial users looking for a top quality, full featured vertical knee type milling machine, built for

Main High Quality Features:

-

- High Grade Meehanite Castings

- Head Swivels Left and Right, AND Tilts Front To Back

- Turcite B way material for smoother table movements

- Hardened and Ground table and way surfaces greatly reduces wear, which maintains accuracy, and greatly extends machine life

- One Shot Lubrication system is standard equipment, which also extends machine life, and reduces

oiling times of all way surfaces and lead screws to seconds, it is accomplished by simply pumping a

lever - High precision Inch Pitch lead screws, for ease of use and greater accuracy (5TPI Screws)

- High Precision Spindle with +/- .0001” or less runout for greater tool life and accuracy

- Balanced pulleys in head for smooth and quiet operation

- Full featured head with automatic quill feeds in 3 steps for boring operations

Precision Honed Quill Bore for tighter tolerance fit, which leads to improved accuracy when drilling and precision boring - The Quill is Precision Ground, then Hard Chrome Plated for longer life

- Available with either step pulley speed changes, or variable speeds to suit the user’s preferences

- Built in coolant sump in machine base

- Tolerance Test Certificate included, each machine is checked for accuracy through a careful

inspection process before shipment, the customer can always be sure they will receive a top quality

machine that exceeds their expectations - Longest in class 5 YEAR WARRANTY against defective parts, including electrical (excludes normal

wear items such as belts, bushings, etc)

Main Specifications:

-

- Model PM-949TS – PM-949TV

- Table Size 9”x49”

- X Axis Travel 34” (Shortened approx.. 2” with X Power Feed Installed)

- Y Axis Travel 13”

- Z Axis Travel (Knee) 16.2”

- Min/Max. Distance, Spindle to Table 2”/18.2”

- Spindle Height: Floor to Bottom of Spindle: 50-1/2”

- Table Height: Fully Raised 49.2”, Lowered 33”

- Quill Travel 5”

- Leadscrew Type Precision Ground ACME Leadscrew W/ Double Nut Backlash Adjustments on X and Y Axis

- Leadscrew Pitch .200” (5 Threads Per Inch)

- Table Dial Graduations .001”

- Spindle Taper R8

- Spindle Speed Range, S Model 80-2720 RPM, 8 steps (40-5000 if you use a VFD)

- Spindle Speed Range, V Model 60-4200 RPM (Variable)

- Spindle Bearing Type High Precision Angular Contact Bearings, Fully Adjustable

- Spindle Bearing Class C7

- Main Motor H.P. 3 HP (Both S and V Models)

- Overall Height, Head Up, 3PHASE/1PHASE – S Model 83.5”/87″ – V Model 85.5″/89”

- Height with head down (For moving and shipping) 68”

- Depth Front to back, rear of machine to front of knee casting 41”

- Rear of machine to tip of Y axis handle 50”

- Width X Axis Table Handles, Tip to Tip 60”

- Net Weight S Model 2350 LBS V Model 2500 LBS

- Voltage / Phase 220 Volt, Single Phase and Three Phase Available – Requires 220 Volt, 20 Amp Circuit for both single or 3 phase

- Warranty: 5 Years

- Shipping Dimensions: LxWxH 60”Wx60”Lx72” H

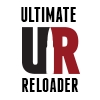

PM-949TV Features and User Interface

Left-Hand Side

On the left-hand side of the machine we have:

- 3hp motor

- Draw bar

- Spindle brake

- Motor control switch (forward/reverse/off)

- Power down-feed direction control (and manual find downfeed)

- Power down-feed selector lever (0.0015″, 0.003″, or 0.006″ per revolution)

- Ram

- Column

- Table

- X-axis feed crank (one on either side of table)

- Z-axis locks (two, only one shown here)

- One shot lube pump/reservoir

- Y-axis lock (on saddle)

- X-axis locks

- Knee crank

- Y-axis crank

Right-Hand Side

On the right-hand side of the machine we have:

- Spindle speed control crank

- High/Low speed range selector

- Power down-feed engagement lever

- 3-axis DRO (optional)

- Ram locks

- Ram movement bolt

- 2-gang power outlet (custom add-on)

- Z-axis DRO scale (part of DRO option)

- X-axis DRO scale (part of DRO option)

- Y-axis DRO scale (part of DRO option)

- X-Axis power feed

Spindle Runout and X/Y Backlash

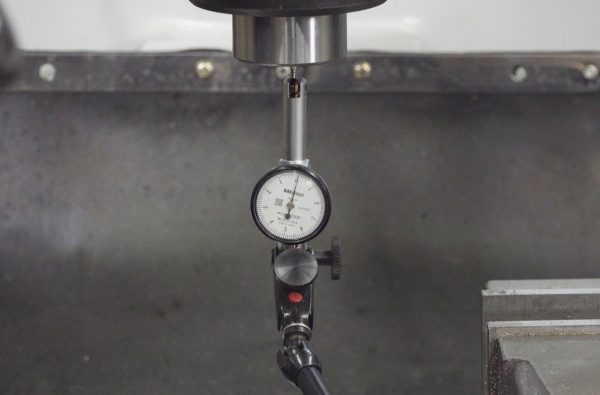

As a part of this “machine tour”, I wanted to include a couple simple measurements related to machine criteria I find important. The first of these is spindle runout!

For the PM-949TV, the acceptable spindle runout spec (listed in the manual) is +/- 0.0001″, or 0.0002″ TIR (Total Indicator Reading, the total sweep of the needle).

As shown in the video, I measured the spindle runout at about 0.00015″ TIR, so my machine is definitely within spec.

The second factor that I checked is the X and Y axis leadscrew backlash. This translates to the total crank movement when reversing feed direction along the X or Y axis *Before* the table starts moving in the opposite direction. A simpler way to describe backlash is the total crank “wobble” possible without moving the table along the X or Y axes.

I measured the X axis backlash at about 0.003″, and the Y axis backlash at about 0.002″. This is very good, and I don’t feel the need to fine-tune backlash on this machine. The backlash is adjustable by means of anti-backlash nuts. There are also tapered gibs for X, Y, and Z axes that can be used to tighten/loosen the table movements long these axes.

PM-949TV Pros and Cons

The PM-949TV Milling machine is a great machine tool. Here are some pros and cons I’ll summarize from my time using this machine: (not including the options that I specified)

Pros

- Fit, finish, quality (top notch), Meehanite castings, Turcite B coatings

- Solid and smooth action

- Variable speed head (100% motor torque over complete speed range)

- R8 spindle taper (lots of tooling options)

- Capacity and table size

- One-shot lube system

- Precision spindle, adjustable/minimal backlash

- Familiar Bridgeport machine layout

- Precision Matthews warranty and support

- Damage-free crating and packing, easy to remove preservative from factory

- Value and configurability/options

Cons

- Plastic fine down-feed crank

- One shot lube fittings needed tightening (small leaks until addressed)

- No coolant system (does have sump)

Summary

My Precision Matthews PM-949TV is really my “dream precision milling machine”. It’s got quality, capacity, and precision. This machine is great for the jobs I use it for, and a great compliment to my heavy horizontal milling machines. I’m looking forward to using this machine for many decades to come! Do you have a Precision Matthews milling machine? I’d love to hear your experiences, please leave a comment!

Don’t miss out on Making With Metal updates, make sure you’re subscribed!

Thanks,

Gavin

Gavin, I have a PM-949 TV mill like the one you have. I am interested in the tool storage rack you made for your’s. Do you have any drawing of spec’s on the one you made. I would like to make one also.