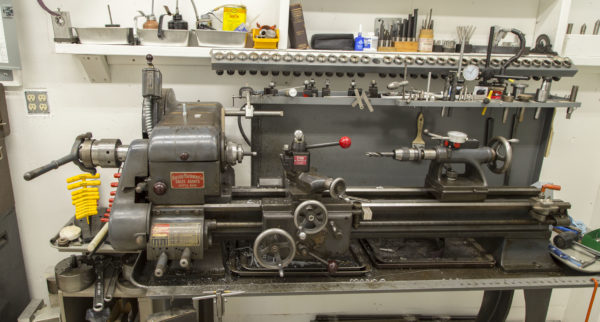

Have you ever owned a tool that seemed to be “a part of you”? My 1955-built Logan model 1922 11″x36″ lathe is one such tool. I’ve owned this lathe for about 15 years now, and if I were to total up all of the hours using this machine, it would be a LOT. I’ve used this lathe to build parts, build tools, remove stuck rifle cases, and many other tasks. I don’t know how anyone can run a shop (or household) without a lathe!

About Logan

Logan lathes were made in the USA, and are of great quality- but they are much less known compared to other brands like South Bend which produced machinery of roughly equivalent quality. Logan is still in business, and you can still buy parts for Logan lathes (see this page).

From the Logan Engineering page on VintageMachinery.org:

Founded in 1935 as the Logan Engineering Company by Henry H. Logan to manufacturer a Hoist Safety Controller. In 1940, the company began Manufacturing metal lathes in 9″, 10″, 11″, 12″, 14″ and 15″ swing sizes under the Logan and as well as Montgomery Ward Powr-Kraft brands (they did not make the Powr-Kraft woodworking lathes). Between 1940 and 1971, Logan Engineering manufactured around 90,000 metal lathes.

In 1968, Logan Engineering was sold to Houdaille Industries, who continued production of metal lathes until 1985. In 1971, Houdaille moved Logan lathe production out of Chicago and into the hands of another Houdaille business, the Tennessee-based Powermatic Machine Co.; having metalworking machines made by a woodworking machinery specialist led to a drop in quality, at least for a time. By about the mid-1970s the Logan lathes were branded “Logan-Powermatic”.

Logan (or Logan-Powermatic) sold milling machines that were made by the Fenlind Engineering Co. See that entry for more information on those “Rockford” style mills.

The Logan Model 1922

When I first met my friend Paul Dunham (A.K.A the “Gizmo Wizard“), he was using what is now my Logan model 1922 for a variety of projects. At the time, I owned a 1953-built South Bend Model A, which had a capacity of 10″ swing, and 24″ between centers. It had a small through-spindle capacity, and lacked a good collet system. I had built a custom r8 collet chuck for it, but that system had its limitations. When I compared my South Bend lathe to Paul’s Logan 11” lathe, I thought- “this would be a great upgrade”.

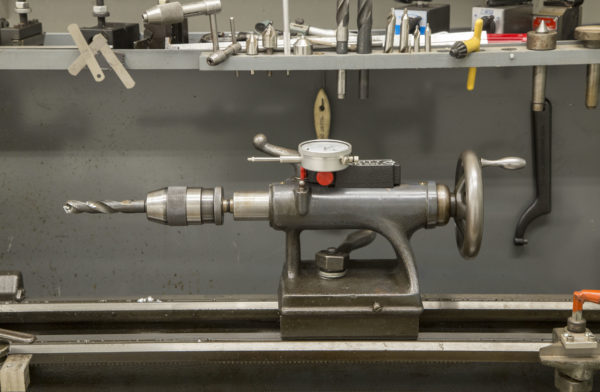

Above: the two-lever quick change gearbox for turning and threading feed adjustment. This kind of setup sure beats change gears!

Here are some of the specs and accessories/tooling that got me interested:

- 1 3/8″ through-spindle capacity- very large for an older lathe of this size!

- 5C collet system: spindle nose, closer lever

- Pre-loaded precision ball bearing spindle (I have measured spindle runout at about +/- .0001″, pretty amazing for a 60-year-old machine!)

- Quick change gearbox

- Power feeds on X and Y axes

- 11″ swing over bed, 36″ between centers

- 3 and 4 jaw chucks plus faceplate

- Dorian AXA size quick-change toolpost and holders

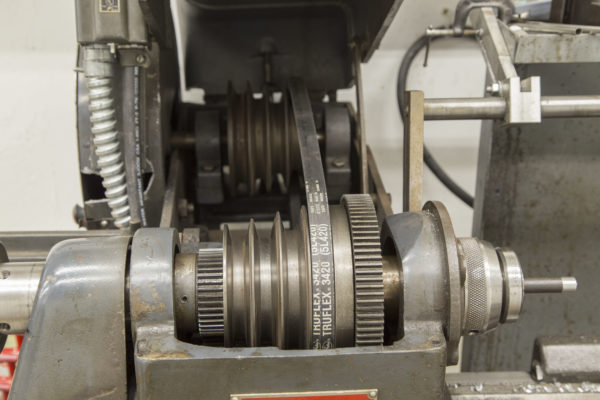

- V-belt drive head (16 speeds total with back-gearing)

- Tailstock taper: Morse Taper #2 (MT2)

Above you can see the v-belt drive used by the Logan model 1922 lathe. Four pulleys, plus a two-speed primary drive, plus back-gearing yield 16 speeds total. Lifting and lowering the belt cover automatically tensions/releases the belts. V-belt drives are great because they offer better grip compared to flat belt drives (I had a flat belt drive on my South Bend lathe) but also offer enough slip to prevent parts from breaking (usually) if a stoppage is encountered.

From the 1953 Logan Engineering Lathe Catalog available on VintageMachinery.org:

Click/tap image to enlarge

Paul ended up buying an amazing Graziano Sag 12 (an Italian lathe with electric-clutch shift on the fly gearbox) and offered to sell me the Logan. I jumped on it! What’s nice about these smaller lathes of yesteryear is their ability to be disassembled and moved with (relative) ease. So I sold the South Bend, and took the Logan home, that was back in 2003. Like most lathe enthusiasts, I’m particular about how my machine is setup and configured, so a journey of “personalization” was embarked upon.

Accessories and Customizations

You can’t own a metal lathe and not add features or tooling to it- that would just never happen. And I’ve added quite a few cool things to this Logan including:

- Full-length sheet metal rear splash guard with integrated top-mounted tool tray

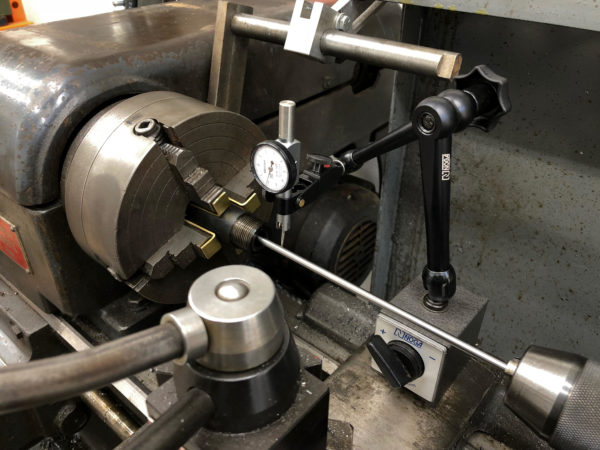

- Milled-top tailstock mod for indicator holders (for precise depth control)

- Headstock Morse Taper #2 adapter for turning between centers

- Carriage mounted die holder

- Wood way protector for chuck changes

- Quick change toolpost tightener

- Outboard spindle spider for rifle barrel work (requires removal of side cover)

Barrel setup for chambering work using 4-jaw chuck and outboard spider

Here’s a picture of the modified tailstock with indicator holder:

Originally, the tailstock had a curved profile on top. Gotta love the old-school styling on these vintage machines, but the curves don’t help when it comes to positioning and mounting measurement tools!

Transition

Over the last 15 years with this lathe, I’ve turned outside diameters, bored inside diameters, drilled, tapped, single-point threaded, reamed, and parted many a part using this machine. It’s been a solid workhorse. Here’s a recent part I needed to fabricate for my milling machine, a zerk fitting adapter (for way oil) to replace an obscure oiler cup. This simple project involved single-point threading, drilling, and parting, and was fashioned from a 3/8″ bolt I had on hand.

It’s GREAT to be able to fabricate whatever you need to solve a mechanical problem, restore a machine, or build something new. Now I’m looking forward to a new chapter in my “Lathe Story”. This week I’ll be taking delivery of a brand new Precision Matthews PM1440-GT precision lathe which is 100% made in Taiwan. Together with my Warner Swasey #2 Turret Lathe, and Grandpa’s 1947-built South Bend 9A which I inherited, I will be “all set” in the manual lathe department. So it may be time to say goodbye to this “trusted companion” – the Logan lathe that has served me well for the last 15 years.

Do you have a Logan Lathe? I’d love to hear your experiences.

Thanks,

Gavin

Helpful video and seems like a nice lathe. I have the chance to purchase a 1915 and wanted to know if you’d be interested in chatting about it and giving me your two cents. Just email me and let me know. thanks

Hi Gavin, I just recently purchased a Logan model 1922 and was curious what lathe tools you have found to be the best as it pertains to turning aluminum?

Any other advise you have as it relates to this lathe would be greatly apprecaited

Keep up the great work

Hi, for Aluminum I’ve had good luck with brazed carbide tools, and indexable carbide tools, they both seem to work well.

I have a 1957 Logan lathe I think is 11 inch.

I’ve been completely through it and everything is good. The issue I have with it is it is weak. It won’t make heavy cuts. It chatters. It hates cutoff tools.

Ive done a lot of work with it but you have to baby it with small shallow cuts . Is there any way to strengthen it up. I’ve changed the bearings in the headstock with new ones but still chatters etc. Are there any special bearings I need to use?

John Hicks

John- I think the answer would be to upgrade to a heavier lathe. I have a Warner Swasey turret lathe that parts off large pieces no problems, all of my smaller lathes chatter and complain a lot with things like parting!

I just acquired an 11″ Logan model 1957. As I learn about lathes, a couple of quick questions. Do you know if accessories from a 10″ Logan will usually fit an 11″. I need a four jaw chuck and other pieces as my lathe did not come with hardly anything extra. Does not even have any of the adjustment wrenches so any of that would be of interest should you have anything to sell.

I sold that entire lathe, sorry!

Hi, great video! Enjoyed seeing your set up. I have a Logan 1922 I just picked up. Question, is there supposed to be a leg under the motor? If so, how tall and how does it mount up. I will need to fabricate one.

I just acquired my Logan Lane 200 about two months ago I have yet to use it it’s been sitting in my storage plan to hook it up soon and maybe get some work done on it it’s a beautiful day and a gentleman and I bought it from said he had it for approximately 40 years he’s been in his basement the whole time it’s well-maintained he was the second owner the first owner I understand had it properly about five years the price that I got for this play was well under what I know he wanted to sell it for but he wanted to get rid of it and he gave it to me and I would call STEEL and he gave me all the accessories that come with it which was under $500 . Are there any books that she would recommend to get all learning about using Lathe.

Gavin….a few years ago I obtained a nice 922 and went thru a 6 month restore process……if you want to see what I did please email me and I’ll send you a link of my entire process one one of the old machine forums.

Hi Gavin, in the past I have had a model 820. I’m in the process of selling my 1949 model 825. Will pick up next week a 11 inch Logan model 1955. Will be nice to have a little more “swing” and larger diameter bore. Charles Crow Penn Valley,Ca