I decided it was time to add another milling machine to my lineup! And this time I’d go smaller- I already have a Precision Matthews PM-949TV (9″ x 49″ Bridgeport clone), but for some jobs, smaller is better. It will also be nice to have a mill that I can leave setup for things like precision drilling.

I chose the new Precision Matthews PM-728VT Ultra-Precision Taiwanese Bench mill, and couldn’t be happier with it! In this video/article, I’ll start with uncrating, cover setup, give a quick tour of the machine, and then do some demos to show the machine in action!

PM-728VT Overview and Specs

From the Precision Matthews Product Page:

PM-728VT Ultra Precision Bench Type Milling Machine

NEW MODEL FOR 2020!

Special Features that set this mill apart from others (BE SURE TO COMPARE THESE DIFFERENCES):

-

- THIS MACHINE IS A STEP ABOVE ANYTHING CURRENTLY ON THE MARKET.

- Ultra High Quality Milling Machine, Made to Exacting Standards. Nothing Else Compares To The Quality Level Of This Mill. If You Want The Best, This Is It. This machine is 100% Made in Taiwan. It Costs More, But You Get More. Much More. The Highest Level of Quality and Precision in a Bench Top Mill Available Anywhere.

- Larger Travels Than Comparable Models, Especially in the Y and Z Axis

- More Weight, Approx. 370 Pounds To Work With. Easy Enough To Move, Heavy Enough To Take Serious Cuts

- Ultra Precision Spindle, with Triple Bearing Support. Deep Groove Ball, and Angular Contact Bearings Run Precise and Stay Cool at High Speeds

- Quill DRO Included Standard (This is for the spindle up/down movement)

- Features a Worm Drive Gear for Tramming Head

- Main Z Axis Column is attached to the base with 4 bolts, and mounted from the top, with a wide, proper mounting surface for much more rigidity over other models in this size range

- .001″ Readings with larger dials on the X and Y axis, with true 10 Thread Per Inch Leadscrews make it easier to cut accurately – (One line on the dial is .001″, one full turn of the handwheel is .100″, much easier to use than those with odd metric conversions)

- Highest Precision ground ways, With Mating Surfaces Hand Scraped To Fit for Much Tighter and Smoother movements – Ultimate High Precision Fit Of Ways and Gibs With This Machine

- Thrust Bearings in leadscrew ends – not bushings – Much smoother movements and less backlash

- Split nuts on X and Y Axis to allow for backlash adjustment

- DC BRUSHLESS MOTOR, Variable Speed, POWERFUL, SMOOTH, and RELIABLE Belt Drive from Motor to Spindle runs MUCH quieter than others, and eliminates any failure prone plastic gears (And the hassle of changing them when stripped)

- 5 Year Warranty, for added peace of mind

Standard Equipment

1. PM-728VT Ultra Precision Milling Machine

2. Chip Tray

3. Variable Speed with Belt Drive and Brushless DC Motor,

4. Way Cover Set

5. Drawbar

6. R8 Spindle Taper

7. Quill/Spindle Depth DRO

8. Spindle Locking Wrench

Optional Accessories

1. Stand with Leveling Feet

2. 3 Axis DRO Installed Note: if a 3 axis DRO is added to the machine, the 3rd axis of the DRO reads the HEAD up and down, Not the quill, so it is not doubling up on the measurement. If you add the 3 axis DRO, now both Z Axis movements are covered)

Main Specifications of model PM-728V-T Ultra Precision Milling Machine:

General Specifications:

Power Requirements: 120V, 20 Amp Circuit (Do Not Use Extension Cords!)

Weight: Machine Net Weight 370 Lbs, Shipping Weight 450 Lbs

Optional Stand Weight: Net Weight 100 Lbs, Shipping Weight 110 Lbs

Cutting Capacities:

Max. Recommended Drilling Capacity 3/4″

Max. Recommended End Mill Capacity 1″

Max. Recommended Face Milling Capacity 3″

Table Specifications and Travels:

Table Size 7” x 28″

Cross Travel (Y Axis) 8.5″ With Full Way Support, 10” to Travel Stop

Longitudinal Travel (X Axis) 17-3/4” With Full Way Support, 19” to Travel Stop

Vertical Travel (Z Axis) 16″

Max Distance Spindle to Table 16-1/4″

Spindle to Column Distance 8-1/2”

Table Leadscrew Pitch 10 TPI (.100″ Per Turn)

Hand Wheel Dial Graduations .001″

Leadscrew Pitch, X, Y, and Z Axis 10TPI

T Slot Size Actual size 12mm, our 1/2″ kit listed is sized for this machine

Head/Spindle/Motor Specifications:

Taper of Spindle R-8, w/7/16-20 Drawbar Thread

Quill/Spindle Travel 3″

Quill Diameter 2.362″ (60mm)

Range of Spindle Speeds 75-4000 RPM, 2 Steps, Variable

Headstock Tilt Left & Right ±90°, With Worm Gear Movement For Easier Tram Adjustments

Motor 1 HP, Brushless DC Variable

Dimensions:

Height (Without Stand) Head At Normal Working Height 36”, Head at Max Travel 44-1/2”

Table Surface to Machine Bottom (Where it sits on the stand or a table) 8-1/2”

Bolt Mounting Pattern of Machine (Where it bolts to the stand) 10-1/8”W x 17-1/2” D, 1/2” Holes

Bottom of machine casting 20-3/4 Deep x 12-1/2” W – 3-1/4 High at Mounting Bolt Surface

Chip Pan Dimensions 21-1/2” W x 24-3/4” D

Stand Height (Stand is optional) 32”

Machine Height (Mounted On Stand) Head At Normal Working Height 68”, Head at Max Travel 76-1/2”

Max Depth, Distance From Rear of machine to front Y Axis Handle Tip 30”

Max Width, Table Handle Tip to Tip 41”

Setting Up the PM-728VT

In my order/shipment was the following:

I used my backhoe (with forks for front loader) to remove the pallet and crate from the shipping truck, and proceeded to take the mill on a “slow ride” up about 1.5 miles of dirt road that leads to the Making With Metal / Ultimate Reloader shop. I set it in place in the shop, and proceeded to cut the straps and remove the box (on top) and top portion of the crate.

Above you can see the chip tray which comes as standard equipment with the milling machine.

Here’s what the milling machine looked like after uncrating/unwraping:

The only things that were required after uncrating/unwrapping were:

- Installing handles and hand wheels (some partially installed from factory as shown above)

- Spraying the machine down with WD-40 and wiping off with rag (removes factory preservative)

- Bolting the machine down to the stand

Machine Features

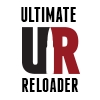

Starting with the left-hand side of the machine, we have (see above)

- Left-hand X-Axis feed wheel

- Table

- On-shot lube reservoir/pump

- Spindle and spindle lock

- Motor control box

- Z-Axis lock (obscured behind motor control box)

- Motor

- Spindle cap

- Pulley/belt cover

- Downfeed DRO

- Quill feed (coarse)

- Quill down feed (fine)

- Right-hand X-Axis feed wheel

- Y-Axis hand feed wheel

- Chip tray

- X-Axis locks (2)

And some things on the right-hand side of the machine not shown in the picture above:

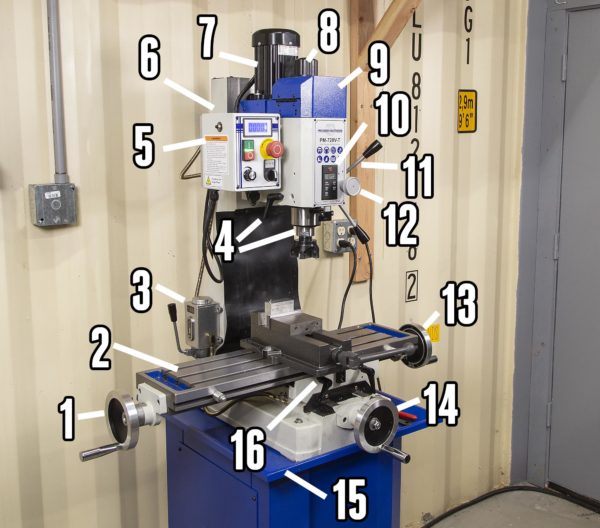

Above we have:

- Z-Axis feed wheel

- Head tilt/tramming worm drive

- One-shot lube tube/fitting

- Head tilt lock and alingnment indicator

- Stand (separate accessory, not included with mill)

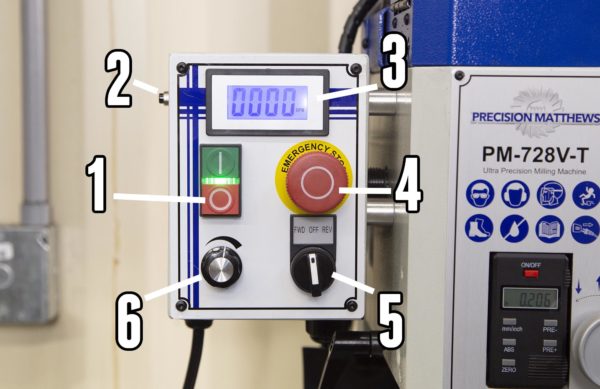

Another important part of this bench mill is the control panel as pictured here:

Above we have:

- On off switch

- Circuit breaker reset button

- RPM display

- Emergency stop button

- Spindle direction control switch

- Speed control knob

Demos

The PM-728VT has an R8 spindle, and that means you are pretty much unlimited when it comes to tooling and accessories! Here are a few of the first things I’ve done with the mill:

Precision Drilling

This machine is super-smooth, and a great machine for precision drilling (especially when I get the DRO installed, which is the next story!)

The PM-728VT is rated at 1/2″ drilling for steel, and I’ll say I had no problem drilling a ~1/2″ hole in mild steel (machine didn’t even slow down!).

End-Milling Operations

Of course you’ll want to perform end-milling operations with your mill, and the PM-728VT is great for that!

Face Milling

A face mill is a GREAT tool to have around when you want to flatten large surfaces, all in one pass typically! In the video I showed a 3″ face mill cutting down the aluminum that we milled a slot on:

This worked great, and I could tell that my cut was conservative, even with just 1hp, I think this machine could take a nice heavy cut!

Speed Range Changeover

The Precision Matthews PM-728VT has two speed ranges: low and high. Changing ranges is straightforward:

- Loosen motor clamping bolts

- Swing motor towards spindle

- Change belt from upper to lower pulleys or vice-versa

- Tighten motor clamping bolts

It’s that easy! With these two speed ranges, this mill can go down to 70 RPM, and up to 4000 RPM! That’s impressive.

What’s Next

I’ve just gotten started with the Precision Matthews PM-728VT! In this series I’ll also cover:

- Install and demo of DRO kit from Precision Matthews

- Comparison of the PM-728TV Bench Mill and the PM-949TV Bridgeport clone

- Ongoing machining stories

If you have something specific you’d like to see, please let me know! (drop a comment)

Don’t miss out on Making With Metal updates, make sure you’re subscribed!

Thanks,

Gavin

I ordered mine w/dro on my birthday last December 2020.

I’m anxiously awaiting it’s arrival for my small garage hobby shop.

Really enjoy your videos and YOU are one of the reasons for my PM-728V-T purchase. I did purchase a PM-12×28 lathe last year as a retirement present and it helped get me through the crazy 2020 pandemic, guess it need a mill as well.

Thank you!

Steve in TN